Risk assessment is a fundamental part of modern Health and Safety Legislation and CE marking Directives. In the UK it is a legal requirement under Management of Health and Safety at Work Regulations (MHSWR) and Provision of Use of Work Equipment Regulations (PUWER) to make risk assessments of all workplaces and work equipment.

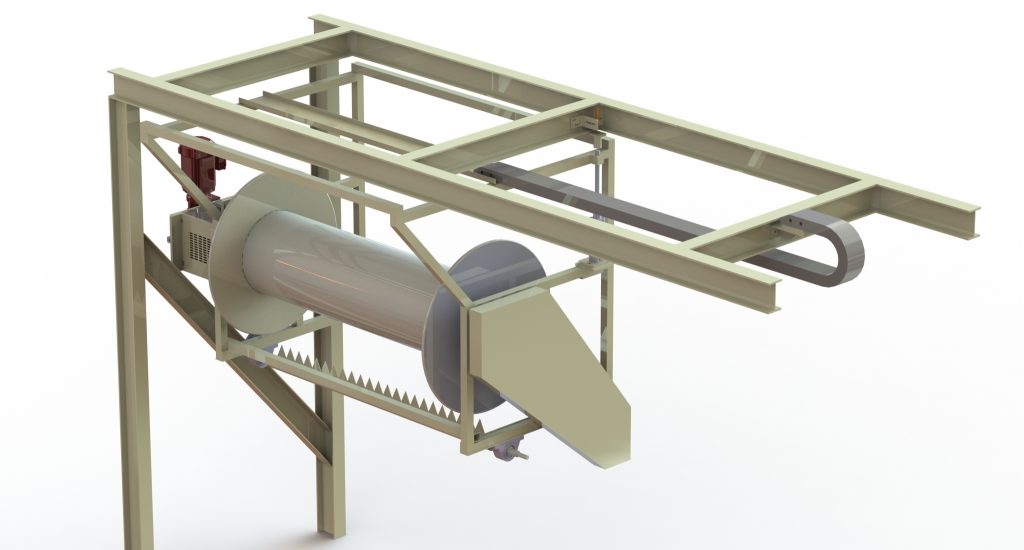

Epsilon Engineering will complete a risk assessment on all the design and build work they undertake for a customer. When done correctly, risk assessment should be a part of the design process and should be started at an early stage. It is always better to design a hazard out than to try to guard against it later.

The process of formal risk assessment will often highlight problems which would be difficult to solve if left too late. In a working environment, risk assessment will help you prioritise safety improvements on a cost benefit and will help you recognise hazards and risks before they have a chance to cause accidents.

During the project Epsilon Engineering will complete a checklist against the EHSRs of the Machinery Directive to allow the user to place their own CE nameplate on the machine and comply with PUWER regulations.

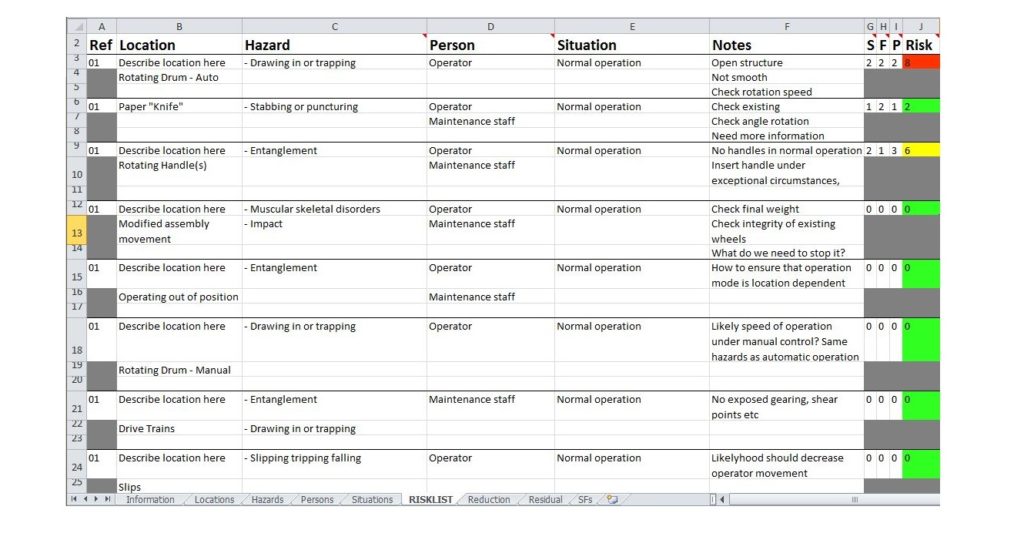

Risk assessment is an ‘iterative’ process involving the identification of hazards and then evaluating the risks they pose. The ideal solution is to eliminate the hazard, which is often not possible, and so we must then consider measures to mitigate risks which are unacceptably high. The process is iterative because once initial measures have been considered the risks are re-evaluated. Once the risks are reduced as low as possible by mitigation, measures to deal with residual risks can be considered. These would typically be warning labels, warnings in user instructions, use of PPE and safe systems of work.

The concept of risk assessment is fundamental to modern Health and Safety legislation. Rather than prescribing fixed solutions, modern legislation places the responsibility on the equipment manufacturer or user to identify hazards and reduce the risk they cause to acceptable levels.

There are many different techniques for risk assessment. There is no one best way and different techniques may be more appropriate in different situations. Epsilon Engineering have made many risk assessments for a wide variety of equipment – can help with risk assessments and advise on the best approach to use in a particular situation.

Epsilon Engineering normally uses a risk assessment method based on an Excel template … please email us and we can send you the file free of charge.